در دنیای امروز پیشرفتهای علمی و دستاوردهای حاصل از آن دارای سمت و سویی است که ارتقاء ایمنی و کاهش خطرات را در جهت بهبود کیفیت محیط زندگی و حفظ جان انسانها نوید می دهد . شاید یکی از بزرگترین ترسهای بشر ، به دام افتادن ، سوختن و مرگ در آتش باشد . از این رو حریق به عنوان یک پدیده خانمانسوز ، همیشه دامنگیر جامعه بشری بوده و خسارتهای مادی و معنوی جبران ناپذیری را بر جای گذاشته است ، بطوریکه انسانها از

انواع رنگ های ضد حریق

رنگ های منبسط شونده پایه حلالی(Intumescent paint)

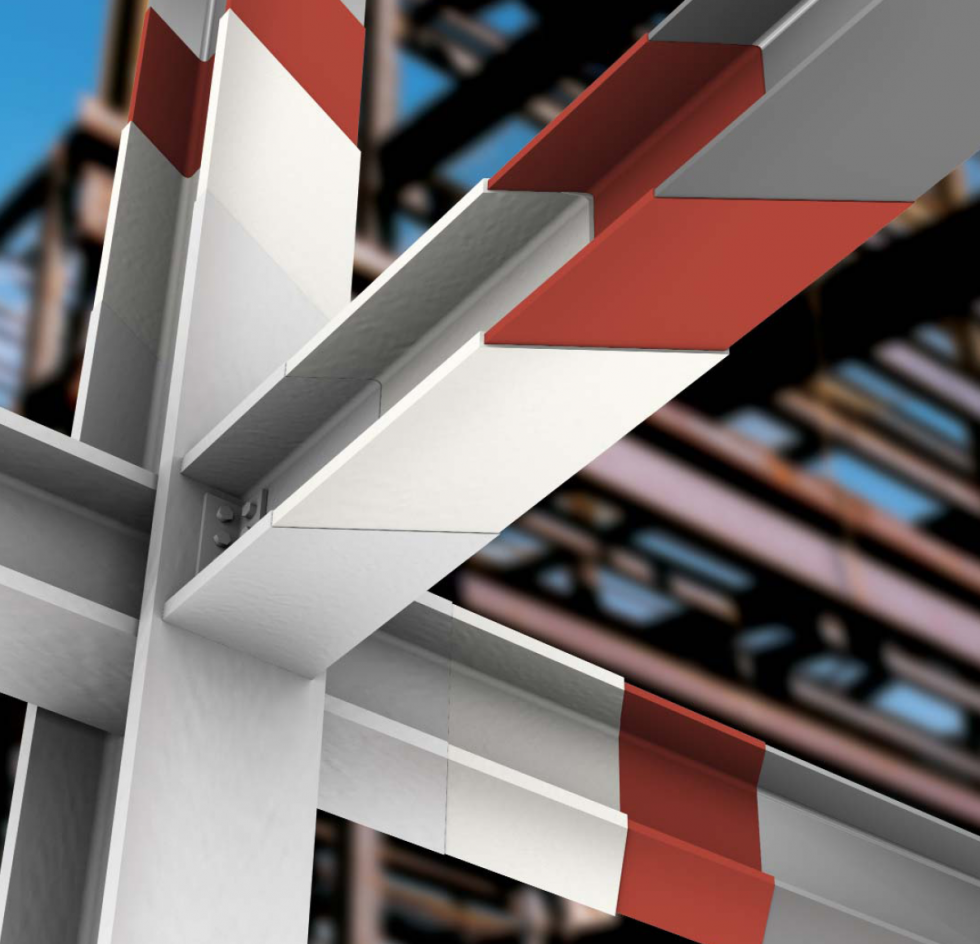

این رنگ ها یک پوشش پایه حلالی حجیم شونده محافظ در برابر حریق جهت مصارف داخل و خارج ساختمان می باشد و بمنظور بالا بردن مقاومتها در برابر حریق در پوشش تیرها و ستونهای فولادی بکار می روند . در این رنگها از حلال برای رقیق سازی استفاده می شود . این نوع رنگ ضد حریق در محیط های باز و مرطوب بیشتر کاربرد دارد.

رنگ های منبسط شونده پایه آبی (Intumescent paint)

پوششهای ضد حریق بر پایه سیمان ( ورمیکیولایت )

پوشش های ضد حریق منبسط شونده (Intumescent paint)

پوشش ضد حریق متورم شونده یا حجیم شونده پوششی می باشد که به محض رسیدن اولین شعله به سطح آن شروع به تورم می نماید و یک فوم جامد مشکی رنگ با ضخامت تقریبی 2/5 cm ایجاد می نماید که فوم پف کرده حاوی میلیونها سلول کوچک ، بسته و مقاوم در برابر حریق است . فوم بعنوان عایق ، تماس شعله با زیر آیند را به تعویق می اندازد و بعنوان یک مانع تاخیر انداز از گرم شدن سریع و احتراق سطح زیرین جلوگیری بعمل می آورد . این فوم عایق تا حدود یک ساعت از رسیدن حرارت به سطح زیرین جلوگیری می نماید و گسترش شعله را به تاخیر می اندازد . در واقع مصالح و موادی که در محیط قرار دارند و می تواند با اولین شعله ، توسعه حریق را بدنبال داشته باشد، استفاده و اعمال پوشش ضد حریق بر روی آن می تواند زمان سوختن چند ثانیه ای را به ساعت تبدیل کند که این خود در شرایط بحران آتش سوزی ، یک فرصت حیاتی غیر قابل تصور بشمار می رود.

نحوه اعمال رنگهای ضد حریق

بمنظور اعمال پوششهای ضد حریق بر روی سازه های فلزی می بایست پس از آماده سازی سطح ، ابتدا پرایمر مناسب برروی سازه فلزی و سپس پوشش ضد حریق را اعمال نمود .

این نوع پوشش به سهولت و در زمان بسیار کوتاه و با ابزارهای مختلف ( دستگاه پاشش رنگ ایرلس ، قلم مو و غلتک) اعمال می گردد و بر روی کلیه سطوح با هر زاویه و شکستگی قابل اعمال هستند . ضخامت اعمالی رنگ بسته به نوع و شکل سازه ، به ضخامت ورق ، شرایط محیطی کاربری ، امکانات اطفا و دیگر عوامل می تواند از حدود 5/0 میلی متر تا 2 میلی متر تعریف گردد . چنانچه نقاطی از سطح که بوسیله پوششهای ضد حریق متورم شونده پوشانده شده در معرض ضربه قرار گیرد و نیاز به ترمیم داشته باشد ، می توان به سهولت و حتی با قلم مو سطح را ترمیم نمود . سطح نهایی این نوع پوشش ضد حریق ، سطحی صاف می باشد بطوریکه پس از اتمام عملیات پوشش دهی نیاز به هموار کردن سطح نمی باشد . به منظور حفاظت از پوشش ضد حریق متورم شونده استفاده از یک لایه رنگ رویه مناسب با نوع ضد حریق توصیه می شود.

پوشش های اسپری شونده معدنی ( Spray Mortars)

پوشش های ضد حریق با خواص معدنی به دو نوع تر ( برپایه سیمان یا گچ ) و خشک تقسیم می شوند. این پوشش ها به دلیل اطمینان از صحت عملکرد و دقت اجرا از رنگ ها و بوردها رایج تر است همچنین نسبت به دو پوشش دیگر از خواص مقاومتی بهتری برخوردار می باشند و می توانند سازه را تا چهار ساعت در مقابل حریق عایق کنند. این مواد به روش پاششی اجرا می شوند.

مواد با پایه اختلاط خشک اصطلاحاً به موادی اطلاق می شوند که به صورت اولیه با آب مخلوط نمی شوند بلکه به جای آن مواد تحت هوای کم فشار انتقال داده می شوند و سپس در خروجی نازل با آبی که به صورت جداگانه به داخل نازل فرستاده می شود مخلوط می شوند. اختلاط تر نشان دهنده این است که محصول قبلاً در محل با آب اختلاط یافته و تبدیل به یک مخلوط روان گردیده و سپس تحت فشار به وسیله تجهیزات ویژه پاشش بر روی سطح پاشیده می شود.